South Pole to Mars: Machinists build some of Chicago’s most precise instruments

By Steve KoppesNews Office

Shop Foreman Dave Plitt | |

A distinguished European scientist appeared unannounced at the University in the early 1950s, when Roger Hildebrand was a young Assistant Professor in Physics.

“He said there was someone he wanted to meet,” said Hildebrand, the Samuel K. Allison Distinguished Service Professor Emeritus in Physics and the College. So Hildebrand asked if he wanted to meet Enrico Fermi, the Nobel Prize-winning physicist and a member of the Chicago faculty.

“He said, ‘Well, no. What I had in mind was meeting Tom O’Donnell.’”

As then-Manager of the University’s central machine shop, O’Donnell had worked closely with the late Albert Michelson, the University’s first Nobel Prize-winning scientist. “Michelson made his mark by extremely precise measurements of various things like the speed of light. Tom O’Donnell was the guy who built that instrumentation,” Hildebrand said.

Today the Central Shop’s machinists continue to build precision instruments for University scientists. Although housed in the Physical Sciences Division, the shop’s services are available to scientists and physicians campus-wide.

Some instruments or components built in the shop now sit on the surface of the moon and Mars, while others fly through deep space on Voyager 1 and 2, far beyond the orbit of Pluto, and other spacecraft. They also occupy the inhospitable environment of Antarctica. The South Pole Telescope detects the afterglow of the big bang, as did its predecessor, the Degree Angular Scale Interferometer, with hardware provided by the Central Shop.

“The shop is an extraordinary resource for the University,” said Steven Sibener, the Carl William Eisendrath Professor in Chemistry and the College. “They make anything from large telescopes to probes for nanoscience. They’re especially good when you need very precise components of large instruments,” Sibener said.

In the area of chemical physics, the shop built sophisticated molecular beam machines for Yuan Lee, a 1986 Nobel laureate in chemistry, when he was a member of the Chicago faculty from 1968 to 1974. The instruments enabled Lee to closely study the dynamics of chemical reactions.

And the University of Toronto’s John Polanyi, who shared the Nobel Prize with Lee and Harvard University’s Dudley Herschbach, also had a large instrument built here because of the shop’s capabilities. “There is a whole generation of people in chemical physics from around the country who had very special instruments built here,” Sibener said.

Sibener earned his Ph.D. at the University of California, Berkeley, under Lee’s direction. Now, virtually every major piece of equipment in all five of Sibener’s laboratories is a product of the Central Shop. His neutral-atom scattering apparatus, for example, allows his team to examine the structure of materials on the atomic scale.

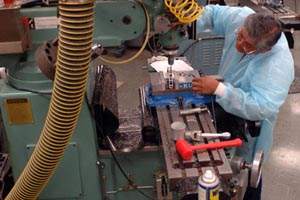

Ernie Mendoza at work in the machine shop | |

“It was built in its entirety in this shop starting about 20 years ago, and it’s been evolving with every generation of students since,” Sibener said. Its precise components required alignments as fine as fractions of a thousandth of an inch over a meter distance, with many components hooked together.

“That is something one could not even contemplate buying commercially. It’s a one-of-a-kind instrument, and it works gorgeously,” he said.

The path between a concept and a new instrument is often a long one, said Stuart Rice, the Frank P. Hixson Distinguished Service Professor Emeritus in Chemistry and the College. Rice noted, “This is not just a shop in which you hand them a set of drawings and say, ‘make it that way.’” Instead, Rice has found that the Central Shop’s machinists have ideas that influence the development and design of his instruments.

“In fact, one of the things that I had built we actually published with the machinist on the experiment,” Rice said.

Four instrument makers staff the shop, including Foreman David Plitt, Ernie Mendoza, Robert Metz and Gordon Ward, along with crane operator Larry Fiscelli.

“The men always have something new to work on,” Plitt said. “They come in every day, start a new job, and they know that’s going to be a new adventure for them.”

Decades ago, the University’s instrument makers numbered in the scores. Plitt laments that skilled machinists are much harder to find these days. “I talked to our union rep. I was telling him, ‘There’s no one out there we can hire.’ He says, “There are no more apprenticeships.’”

Existing training programs do little more than teach the basics, Plitt said, and they fall short of the skills and artistry needed to work in his shop. “Aesthetics is very much a part of it,” Rice said. “A really precise machine is a beautiful thing.”

![[Chronicle]](/images/sidebar_header_oct06.gif)