Optical fractionation technique takes HOT technology to new level of sorting particles

By Steve KoppesNews Office

![[diagram]](optical-diagram.jpg) Holographic optical tweezers are used to create a lattice of discrete optical traps through which small objects, such as proteins or biological cells, are driven by flowing fluid. The fluid is contained in a small transparent sample chamber into which the laser traps are projected with a microscope objective lens. The array, shown schematically in the inset, is created from a single laser beam with a computer- designed diffractive optical element and is deliberately inclined with respect to the direction of fluid flow. A digital camera with a charge- coupled device is used to monitor the objects’ motions through the traps. |

Grier and Pamela Korda, (Ph.D., ’02), with assistance from Michael Taylor, a participant in the University’s Research Experiences for Undergraduates Program, discovered the principles underlying optical fractionation.

The potential applications for it include routine medical testing, pharmaceutical research and the development of entirely new biotechnological markets.

With funding from the National Science Foundation, Physics graduate student Kosta Ladavac and fourth-year Physics concentrator Karen Kasza are collaborating with Grier in further development of the technique.

Optical fractionation is based on holographic optical tweezers technology. HOT technology uses forces exerted by strongly focused, computer-generated holograms to create very large arrays of discrete optical traps. Each trap is capable of suspending a microscopic object motionless in three dimensions.

Using HOT technology is like having microscopic hands. “You can really reach in, move things relative to each other, orient them, bring them together, take them apart, and, to an increasing degree, transform them,” Grier said.

The technology is based on the principle that dielectric particles–those that do not conduct electric current–experience forces that draw them to where the light is brightest.

With optical fractionation, forces exerted by flowing fluid drive the objects of interest through an array of optical traps created by the HOT technology. Depending on the competition between the driving force and the forces exerted by the optical traps, the objects can either continue in their original direction or get deflected into a new direction that is dictated by the asymmetry of the array.

Optical fractionation is complementary to and more flexible than existing techniques such as gel electrophoresis, Grier said. Almost all of the existing techniques involve a competition between two forces that act in opposite directions along the same axis. In the case of gel electrophoresis, an applied electric field drives objects such as DNA in one direction, while the viscous drag of the gel opposes that motion.

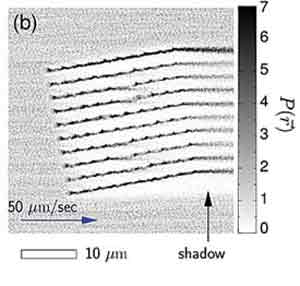

Combined trajectories of 40,000 particles, each one micrometer in diameter, show a striking deflection by the trap array. Other objects that interact less strongly with the trap array flow through unimpeded into the shadow downstream where they can be collected. Grayscale in this image measures the average local density of particles relative to their density in the undeflected flow. |

One also can adjust the laser wavelength and power and the trap geometry, allowing the traps to instantly sort objects ranging in size from less than 100 nanometers (the size of the Human Immunodeficiency Virus), to near 100 micrometers (the diameter of a human hair).

“All you change is the latticework of light, which results from a computer-generated hologram,” Grier said. “What you’re changing is one line of software.”

Grier and his group so far have received two patents on the technology. His team continues to extend the technology’s applications and now has 20 patents pending both domestically and abroad. Arryx Inc., a Chicago company based on Grier’s HOT technology, developed the BioRyx™ 200 system, which R&D Magazine selected as one of the 100 most technologically significant products of 2002.

Arryx Inc. already has conducted an analysis of the existing cell fractionation market, said Ken Bradley, a founder and chief operating officer of Arryx.

“There are existing companies using different techniques that sell tools for cell sorting, and those markets are in excess of a billion dollars a year,” Bradley said. “You would not displace that entire market, but those are the sorts of numbers you get.”

Optical fractionation also is one element needed to transform microfluidics from a plumbing system to a factory, Bradley said. One example of the latter would be using HOT technology to produce labs-on-a-chip. The idea is to make medical testing faster and less expensive than using a full-scale laboratory with human technicians.

With a lab-on-a-chip, Grier said, “you would just squirt some sample in, push a button and the chip would do all the work. It would shuttle all the chemicals around, do all the testing, and then report the results through some sort of human interface. Optical tweezers are one way to create structures that actually do the analysis.”

![[Chronicle]](/images/sidebar_header_oct06.gif)